HIGH SOLDARーG:Agent with improved solder wettability for nickel plating

Purpose:Heat and electrical insulation

HI SOLDAR―G is improved solderability of Ni plating by dipping after plating.

Characteristic

- Improve solderability of Ni plating

- No prevent conductivity

- Prevent oxidation of Ni plating film

- Easy treatment

Application

Used for connectors, lead frames, print substrate, nickel hoop plating, etc.

Peformance

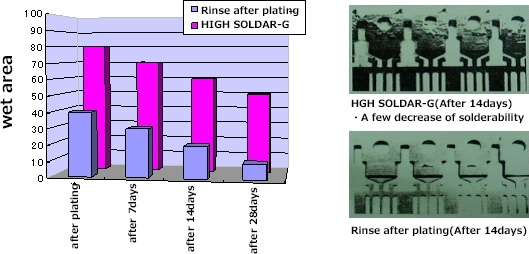

Ageing of Solderability(6/4 Solder、230℃-10sec-No flux)

Test piece:Bright Ni(Watts Ni bath)

Peformance

-

Concentration 100~200 ml/L

Dissolution Pure water at 30℃

- Temperature Room temperature (20~30℃)

- Time 20~30 Sec.

- Ni plating ⇒ Rinse ⇒ Rinse ⇒ Dip into HIGH SOLDAR―G ⇒ Rinse ⇒ Dry

- Possible to use for Mat plating, Bright, Electroplating, Electroless plating.

- If solderability decrease by long standing, solderability recover by HIGH SOLDAR―G after reactivation.