ELECOAT EU-XC:A negative photoresist electrodeposition process for masking of partial plating or etching

Purpose:UV Curing negative acrylic cation electrodeposition coatings

EU-XC process is negative type of acrylic cation electrodeposition coatings that is curing by UV. It is consisted by Resist coatings, Developer and Remover.

It is applicable in all platings and metallic materials because of the cation type. Since it is developed by acid solution, it excels in alkali resistance, it is the best for alkali plating resist, such as cyaniding silver plating.

It is applicable in all platings and metallic materials because of the cation type. Since it is developed by acid solution, it excels in alkali resistance, it is the best for alkali plating resist, such as cyaniding silver plating.

Characteristic

- It is applicable in all materials because of the cation type.

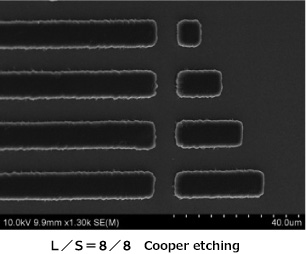

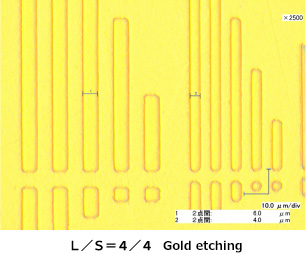

- Excellent tackiness, edge covering, so good accuracy after developing.

- It is applicable in the hoop line because good film formation in a short time.

Application

- In stead of dry film for PCB

- Part resist for lead frame

- Etching resist for precise etching pattern

- Face plate, relief decorative etc.

Electrodeposition Photo Process

| Operations | Processing Conditions | Chemicals Used |

|---|---|---|

| Cleaning and activation | Cleaning and activation by a chemical solution | Various detergents and activation agents |

| Resistive electrodeposition | 30-60 sec | Elecoat EU-XC series |

| Drying | 60-80℃ (140-175°F), 30-60 sec | |

| Exposure | 100-150mj/cm2 (i beam) | |

| Development | 40-50℃ (105-120°F), 30-60 sec | Special developing fluid (acidic) |

| Plating or etching | ||

| Photoresist stripping | 40-50℃ (105-120°F), 30-60 sec | Special stripping solution (acidic) |

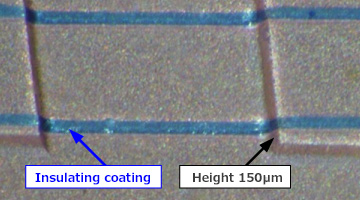

Creating an Insulating Coating on a Surface is Easy

Electrodeposition photoresist can easily create an insulating coating on even difficult textured surfaces through filming, dipping, or applying.