ELECOAT IE:Electrodeposition Coating for Small Devices

Purpose:Insulating film for various devices and metal substrate, other general insulation

This coatings is the electrodeposition coatings that are the most suitable for the precise insulation of the small electronic part.

It can form a uniform excellent film in the insulation on the edge safely.

It can form a uniform excellent film in the insulation on the edge safely.

Characteristic

- Because based by Imide amide-epoxy resin, it has good heat resistance.

- Because good edge covering and pin-hole less process, it can get high voltage resistance. It has good hardness, heat resistance, solvent resistance.

- It has good hardness, heat resistance, solvent resistance.

- Because this is cation type, so all material is OK.

Application

Motor core, PCB or for insulation parts

Process

-

Process Conditions

Electrodeposition coating: 50-200V, 2 min

Liquid temperature: 30℃ (85°F)

Preliminary drying: 80-100℃ (175-210°F), 15+ min

Baking and drying: 190-210℃ (375-410°F), 40 min

-

Film peformance

ITEM RESULT Voltage resistance 1000V(10μ) TG 130℃ Volume resistivity 1016Ωcm Dielectric constant 5~6 5% Weight lossTemperature 180℃ Adhesion 100/100(By JIS) Hardness 5H

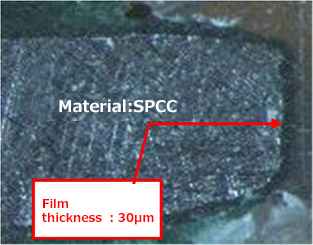

Other (Cross-sectional view of Film)

- Good heat resistance

- Good insulation

- Possible to control ~40μm ofthickness

- Good edge covering