ELECOAT ALS:AL anodizing substitution technology by ELECOAT

Purpose:Insulating film for various devices and metal substrate, other general insulation

We provide colorization with Elecoat as an alternative to alumite treatment

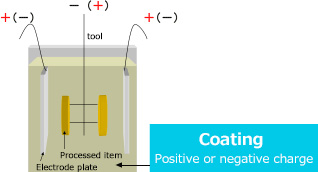

Principles of Elecoat

About the Elecoat (Electrodeposition Coating) Process

Elecoat is a water-soluble coating with a positive or negative charge, coating an object in minimal time using electricity. The coated part becomes an insulator, the uncoated part becomes more electrically conductive, and a uniform coating can be achieved.PROCESS(Patent pending)

Standard process

- Low cost such as anodizing

- Good glossiness

- Good light resistance

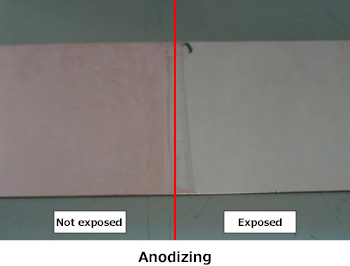

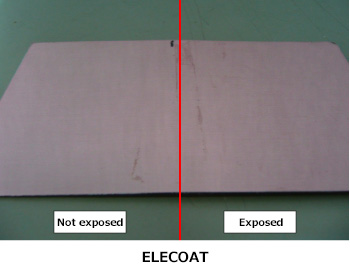

COMPARE with anodizing

| ELECOAT | ANODIZING | |

|---|---|---|

| Color variation | ◎(ALL color is OK) | △(Cannot white color) |

| Color stability | ○ | △ |

| Lightresistance | ◎(Use pigment) | ×(Use dye) |

| Brightness | ◎ | △ |

| Cost | ○ | ○ |

COMPARE with anodizing

COMPARE with other coating method

| Characteristic | ELECOAT | Electrost atic coating | Spray coating | Powder coating |

|---|---|---|---|---|

| Throwing power electrolytic | ◎ | △ | × | △ |

| Edge covering | ○ | × | × | △ |

| Throwing power | ◎ | ○ | ○ | × |

| Leveling | ◎ | ○ | ○ | △ |

| Environmental | ○ | △ | △ | ○ |

ELECOAT has excellent throwing power and can get leveling film.